Zirconia for Industrial Applications

We supply zirconia materials engineered for industrial and technical ceramic applications—delivering the phase stability and process consistency your manufacturing line demands.

3+

Stabilization Systems

Y₂O₃, MgO, CaO and custom compositions available

0.1–5μm

Particle Size Range

Precise D50 control for optimal sintering results

≥99.5%

Purity Level

High-purity grades for demanding applications

100%

Batch Tested

Every batch verified against reference standards

Direct Manufacturer

In-house production with full process control from raw materials to finished powder

Customizable Specs

Adjust particle size, stabilizer content, and other parameters to your requirements

Complete Documentation

COA, TDS, and compliance documents ready for international shipments

Find the right zirconia grade for your application.

Talk to Our EngineersZirconia Types Overview

Explore our range of zirconia grades designed for different performance requirements and processing conditions

YSZ

Yttria-Stabilized Zirconia

Stabilization

Y₂O₃ (3–8 mol%)

Key Properties

Exceptional fracture toughness, ionic conductivity, high flexural strength

Applications

PSZ

Partially Stabilized Zirconia

Stabilization

MgO or CaO (partial)

Key Properties

Transformation toughening, thermal shock resistance, excellent wear performance

Applications

Monoclinic

Unstabilized Zirconia

Stabilization

None (pure ZrO₂)

Key Properties

High chemical stability, excellent corrosion resistance, raw material for stabilized grades

Applications

Custom Grades

Application-Specific Formulations

Stabilization

Tailored (CeO₂, Y₂O₃, etc.)

Key Properties

Optimized for specific sintering profiles, density targets, or mechanical requirements

Applications

Need help selecting the right zirconia type for your process?

Get Technical RecommendationsPhase & Stabilization Logic

Understanding zirconia phase structures helps you select materials that deliver the exact performance characteristics your application demands

Why Stabilization Matters in Zirconia Performance

Pure zirconia undergoes destructive phase transformations during thermal cycling—expanding and contracting in ways that cause cracking and mechanical failure. Stabilization with oxides like yttria (Y₂O₃) or magnesia (MgO) locks the crystal structure in beneficial forms, enabling the material to withstand demanding conditions.

Different phase structures offer distinct advantages: tetragonal phases provide exceptional toughness, cubic phases deliver superior ionic conductivity, and controlled phase mixtures enable transformation toughening. Selecting the right stabilization system allows you to optimize strength, thermal stability, and wear resistance for your specific process.

Zirconia Phase Structures Explained

Monoclinic Phase

Stable below ~1170°C

The room-temperature form of pure zirconia. While chemically stable, unstabilized monoclinic zirconia is prone to destructive volume changes during heating and cooling cycles.

- Lowest density of all phases

- Chemical inertness for pigments

- Base material for stabilization

Tetragonal Phase

Stable ~1170°C – 2370°C

Retained at room temperature through yttria or ceria stabilization. This phase enables transformation toughening—absorbing crack energy by converting to monoclinic under stress.

- Exceptional fracture toughness

- High flexural strength

- Ideal for structural ceramics

Cubic Phase

Stable above ~2370°C

Achieved with higher stabilizer concentrations. Cubic zirconia offers excellent high-temperature stability and ionic conductivity, making it essential for solid oxide fuel cells and oxygen sensors.

- Superior ionic conductivity

- Excellent thermal stability

- Critical for electrochemical uses

How Stabilization Affects Performance

Different stabilizers and concentrations enable you to fine-tune material properties for specific manufacturing outcomes

Enhanced Toughness

3Y-TZP formulations retain tetragonal phase for transformation toughening—ideal when crack resistance is critical to product reliability

Thermal Stability

Higher yttria content (8YSZ) creates cubic phases that maintain structure through thermal cycling—essential for high-temperature environments

Wear Resistance

PSZ with magnesia stabilization combines hardness with shock resistance—delivering longer service life in abrasive applications

Unsure which phase structure suits your application? Let our engineers guide you.

Request Technical ConsultationTypical Applications

Our zirconia materials are selected based on the performance requirements of your end product—not just industry categories

Wear Resistance & Strength

Structural Ceramics

When your components face constant abrasion and mechanical stress, YSZ and PSZ grades deliver the hardness and toughness that extend service life and reduce replacement costs.

Thermal Stability

Refractories & Insulation

High-temperature environments demand materials that maintain structural integrity through repeated thermal cycles. Our stabilized grades resist thermal shock while providing excellent insulation performance.

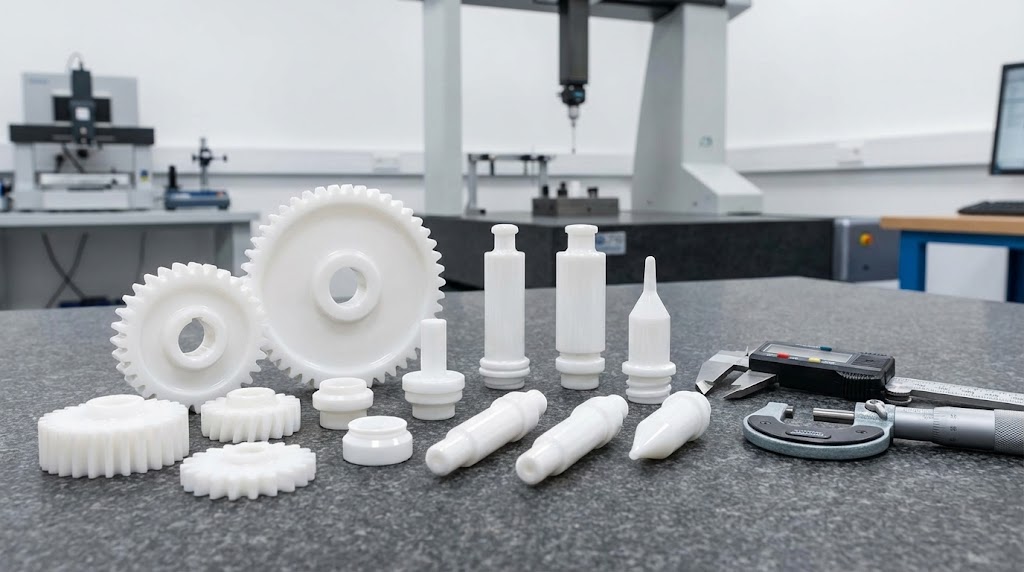

Precision & Density

Technical Ceramic Components

Achieving tight tolerances and high sintered density requires powder with controlled particle distribution. Our grades enable predictable shrinkage and superior surface finish in precision parts.

Biocompatibility

Dental & Medical Ceramics

Biomedical applications demand exceptional purity and consistent mechanical properties. Our high-purity YSZ grades meet the stringent requirements for dental restorations and implant components.

Application-First Material Selection

We don't simply categorize by industry—we match zirconia grades to the specific performance characteristics your process requires. Tell us your application challenges, and our engineers will recommend materials that deliver measurable improvements in your production outcomes.

Describe your application requirements—we'll recommend the optimal zirconia solution.

Submit Your Application DetailsKey Specifications Snapshot

Quick reference for engineers and procurement teams evaluating zirconia materials

Particle Size (D50)

0.1 – 5.0 μm

Customizable to match your sintering requirements

Purity Level

≥99.5% – 99.9%

High-purity grades for demanding applications

Stabilizer Content

Y₂O₃: 3–8 mol%

MgO, CaO, CeO₂ options available

Bulk Density

0.8 – 1.5 g/cm³

Controlled for consistent processing

Note: These are typical specification ranges. Complete Technical Data Sheets (TDS) are provided upon request to match your specific application requirements. We customize parameters based on your processing conditions.

Need detailed specifications for your evaluation?

Request Full SpecsConsistency & Processing Control

Repeatable performance isn't accidental—it's engineered. Our production process is designed to eliminate variability, ensuring that every batch meets the same specifications that qualified your initial samples.

Raw Material Control

Incoming materials are tested and qualified before entering production to ensure consistent starting points

Processing & Classification

Controlled milling and classification processes deliver precise particle size distributions

Phase Consistency Management

Stabilization and calcination parameters are monitored to maintain target phase compositions

Batch-to-Batch Stability

Every batch is tested against reference standards before release to production

How to Choose the Right Zirconia Grade

Match your performance priorities to the optimal material—here's a quick guide to help you decide

If You Need

Maximum Fracture Toughness

Your components face impact loads, crack propagation risks, or need to survive mechanical shock without catastrophic failure.

Recommended

3Y-TZP (3 mol% Yttria)

If You Need

High-Temperature Stability

Your application operates above 1000°C or experiences repeated thermal cycling that destabilizes lower-yttria grades.

Recommended

8YSZ (Cubic Phase)

If You Need

Wear & Thermal Shock Resistance

Your parts face abrasive environments combined with rapid temperature changes—requiring both hardness and shock tolerance.

Recommended

Mg-PSZ or Ca-PSZ

Common Selection Mistakes to Avoid

Using 3Y-TZP above 400°C in humid environments — Low-temperature degradation can compromise tetragonal phase stability over time

Choosing by purity alone without considering phase — High purity doesn't guarantee the mechanical properties your application needs

Ignoring particle size effects on sintering — The wrong D50 can lead to density problems or excessive shrinkage variability

Not sure which grade fits your application? Our engineers can help you decide.

Get Expert RecommendationsWhy Work With Us

What makes us different from other zirconia suppliers

Zircon-Focused Expertise

We specialize in zirconium-based materials—not a general chemical catalog. Deep focus means deeper knowledge.

Application-Oriented Support

Our engineers understand your processes and help match materials to your specific manufacturing challenges.

Consistent Quality

Batch-to-batch repeatability means fewer production surprises and more predictable outcomes for your process.

Export-Ready Documentation

Complete COA, TDS, and compliance documentation prepared for international shipments and audits.

Ready to discuss your zirconia requirements?

Start a ConversationGet in Touch

Have questions about our zirconia materials? We're here to help.

Frequently Asked Questions

Do you support custom zirconia grades?

Yes. We can adjust stabilizer content, particle size distribution, and other parameters based on your specific application requirements.

What is your minimum order quantity?

MOQ varies by grade. Standard grades start from 100kg; custom formulations may require larger commitments. Contact us for specific requirements.

Can I get samples for testing?

Absolutely. We provide evaluation samples for qualified projects. Tell us about your application and testing needs.

What applications do you mainly serve?

Technical ceramics, refractories, dental/medical, fuel cells, and precision engineering components are our primary focus areas.

Send Us Your Requirements

Please tell us your application and required properties. Our team will help select the suitable zirconia material.