Dental Materials Demand Absolute Reliability

When zirconia enters the dental system, there's no margin for variability. Every batch must perform identically—because in dental applications, material consistency isn't just a quality metric, it's a commitment to patient safety and clinical outcomes.

The Hidden Risks in Dental Material Supply

Dental manufacturers face unique challenges that go beyond standard material specifications. These issues directly impact product quality, regulatory compliance, and patient outcomes.

Batch-to-Batch Processing Variance

Materials that meet spec sheets can still behave differently during CAD/CAM milling or sintering. What looks identical on paper creates unpredictable results on the production floor.

Narrow Processing Windows

Dental zirconia requires precise sintering temperatures and times. Minor material variations can shift the optimal window, causing yield fluctuations that erode margins.

Long-term Performance Uncertainty

Initial testing passes, but how will restorations perform after years in the oral environment? Without material stability data, you're betting on outcomes you can't predict.

Incomplete Traceability Chain

When a quality issue emerges, can you trace it back to specific material lots? Gaps in documentation create compliance risks and make root cause analysis nearly impossible.

Evolving Compliance Requirements

Regulatory standards continue to tighten. Suppliers who can't maintain consistent documentation and quality systems become a liability rather than a partner.

Slow Technical Communication

When processing issues arise, you need answers fast. Suppliers without dedicated technical support leave you troubleshooting alone, wasting time and materials.

Experiencing any of these challenges? Let's discuss how to address them systematically.

Why Dental Applications Demand More from Zirconia

The oral environment creates unique demands that expose any weakness in material consistency. Understanding these factors reveals why standard industrial specifications fall short for dental applications.

Microstructure Controls Macroscopic Reliability

Grain size, phase distribution, and porosity at the nanometer scale directly determine fracture resistance and long-term stability. Subtle variations create outsized impacts on clinical performance.

Phase Purity Determines Transformation Behavior

The tetragonal-to-monoclinic transformation that gives zirconia its toughness must be precisely controlled. Impurities or processing inconsistencies can trigger unwanted transformations over time.

Decades of Service in Harsh Conditions

Dental restorations must withstand moisture, temperature cycling, mechanical loading, and chemical exposure for 10-20+ years. Materials must be engineered for longevity, not just initial performance.

"In dental applications, material consistency matters more than any single performance metric. Predictable behavior, batch after batch, is the foundation of clinical confidence."

Want to understand how material properties affect your specific application?

Rethinking Dental Material Selection

Traditional procurement approaches often overlook the factors that matter most for dental applications. A shift in evaluation criteria can dramatically improve outcomes.

| Evaluation Factor | Traditional Approach | Reliability-Focused Approach |

|---|---|---|

| Specification Review |

Focus on data sheet parameters only

|

Evaluate processing behavior and consistency data

|

| Qualification Testing |

Single sample lot evaluation

|

Multi-batch validation with historical data

|

| Supplier Relationship |

Single-source or lowest-price selection

|

Partnership based on technical capability

|

| Cost Evaluation |

Per-unit material price comparison

|

Total cost including yield, rework, and compliance

|

Ready to implement a reliability-focused approach to material selection?

The Four Pillars of Dental Material Excellence

These core standards define what dental material manufacturers should require from their zirconia suppliers. Each pillar addresses a critical aspect of long-term success.

Batch Consistency & Reproducible Processing

Every shipment should behave identically in your process. Tight statistical control on particle size, surface area, and morphology ensures predictable milling, pressing, and sintering behavior across production runs.

Controlled Phase Structure

Precise yttria distribution and phase composition are essential for optimal mechanical properties. Clear documentation of phase ratios and stabilizer content provides confidence in long-term transformation stability.

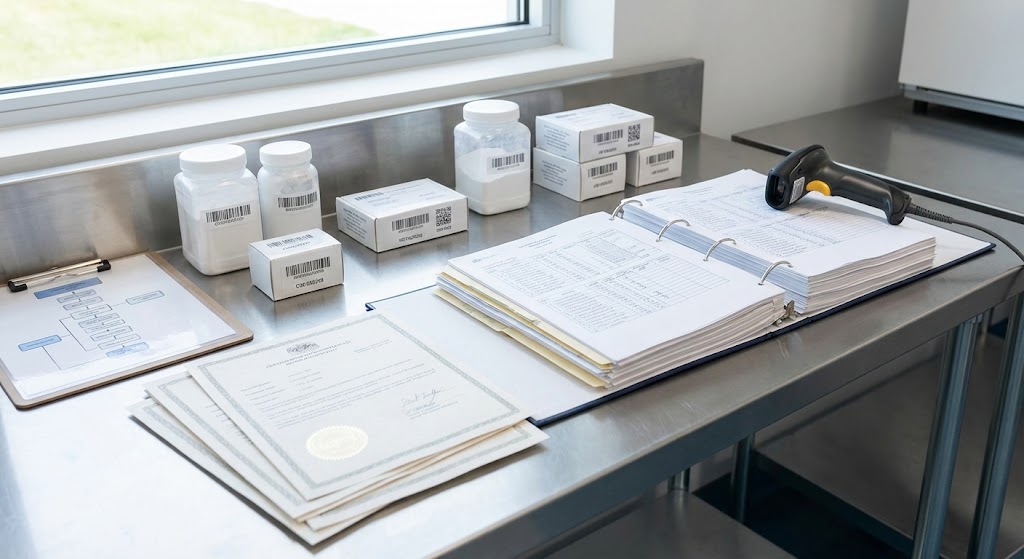

Complete Quality & Traceability System

From raw material sourcing through final packaging, every step should be documented. Comprehensive batch records, certificates of analysis, and clear lot identification support regulatory compliance and issue resolution.

Long-term Supply & Technical Partnership

Reliable supply isn't just about inventory—it's about maintaining consistent quality over years. Dedicated technical support and proactive communication ensure smooth operations and continuous improvement.

Let's discuss how these standards apply to your specific requirements.

How We Approach Dental Material Solutions

We view dental zirconia not as a simple commodity, but as a precision-engineered system where every variable matters for clinical outcomes.

Dental applications represent one of the most demanding environments for zirconia materials. We approach this challenge by treating each material as a complete system—not just raw powder, but a carefully controlled product designed to perform predictably throughout your entire manufacturing process.

Our engineering team focuses on the factors that actually impact your results: how materials behave during CAD/CAM processing, how they respond to different sintering profiles, and how finished restorations will perform over years of clinical service.

Want to understand our engineering approach in more detail?

Zirconia Systems Engineered for Dental Excellence

Our material portfolio addresses the full spectrum of dental application requirements, from high-strength frameworks to translucent aesthetic restorations.

Zirconia for Digital Dentistry

Precisely controlled powders optimized for pressing and milling applications, delivering consistent green machining behavior and predictable sintering shrinkage across every batch.

Controlled Phase Zirconia

Materials with precisely managed yttria content and phase composition, ensuring optimal transformation toughening and long-term stability in the demanding oral environment.

Reliability-Focused Systems

Complete material systems backed by comprehensive documentation, including full batch traceability, certificates of analysis, and processing guidelines for consistent results.

Need help selecting the right material for your application?

Where Our Dental Materials Are Applied

Our zirconia materials support a wide range of dental industry applications, each requiring specific material characteristics for optimal performance.

Dental Restoration Manufacturing

Crowns, bridges, and implant abutments requiring consistent sintering behavior

CAD/CAM System Integration

Materials optimized for major digital dentistry platforms and workflows

Dental Laboratory Production

High-consistency materials for commercial lab environments

Material R&D Programs

Characterized materials for product development and research

Medical Ceramic Components

Precision materials for specialized medical device applications

Working on a different application? Let's discuss your specific requirements.

Why Dental Customers Choose Long-term Collaboration

In an industry where material consistency directly impacts patient outcomes, our customers value these aspects of working with us.

Proven Supply Reliability

Years of consistent delivery performance with safety stock management. Your production schedule stays on track because your material arrives when expected, every time.

Complete Documentation

Full batch traceability with comprehensive certificates of analysis. When auditors or customers ask questions, you have complete answers backed by data.

Direct Engineer Access

Technical questions go directly to engineers who understand your application, not through layers of sales support. Fast, knowledgeable responses when you need them.

Deep Material Experience

Decades of zirconia expertise applied to your challenges. We've seen and solved problems across the full spectrum of dental material applications.

Ready to experience a different kind of supplier relationship?

Looking for a Reliable Dental Materials Partner?

If consistency, traceability, and long-term reliability are critical to your dental materials program, a technical discussion is the right place to begin. Our engineering team is ready to understand your requirements and explore how we can support your success.