High-Performance Zircon Materials for Industrial & Technical Applications

Engineered zircon solutions with controlled PSD, stable whiteness, and verified phase composition — designed to reduce process variation and quality risk.

Who We Serve

Tailored zircon materials solutions for industries where material performance is non-negotiable

Sanitary Ceramics

Key concerns: Whiteness consistency, glaze surface smoothness, batch-to-batch stability for automated production lines.

Refractory Industry

Key concerns: Thermal shock resistance, high-temperature stability, controlled particle distribution for dense packing.

Investment Casting

Key concerns: Shell strength, slurry rheology control, dimensional accuracy for precision parts.

Advanced Ceramics

Key concerns: Phase purity (tetragonal/monoclinic), sub-micron PSD, sintering behavior predictability.

Ceramic Glaze & Pigment

Key concerns: Color development consistency, opacity control, dispersion in glaze formulations.

Grinding Media & Parts

Key concerns: Wear resistance, density uniformity, mechanical strength after sintering.

Don't see your industry? Let's discuss your specific application requirements.

Our Services

More than a supplier—engineering support from material selection to production

Grade Selection Support

- 1 Analyze your application requirements and process conditions

- 2 Match with suitable grades from our portfolio

- 3 Provide technical comparison and recommendations

Samples & Data Package

- 1 Send representative samples for your testing

- 2 Provide complete test reports with each shipment

- 3 Support your qualification process with data

Custom Specifications

- 1 Define target PSD, whiteness, or phase composition

- 2 Adjust production parameters to meet your specs

- 3 Validate through trial batches before scale-up

Stable Long-term Supply

- 1 Establish agreed specifications and quality standards

- 2 Implement batch consistency monitoring

- 3 Maintain safety stock for your scheduled orders

Ready to optimize your material performance with engineering support?

Why Stability Matters

In precision manufacturing, batch inconsistency costs more than the price difference

| Performance Indicator | Typical Supplier | ZrBrontec |

|---|---|---|

| PSD Consistency (D50 variance) | ±15% | ±5% |

| Whiteness Batch Variance | ±3 units | ±1 unit |

| Full Test Report Provided | On request | Every batch |

| Batch Traceability | Limited | Full chain |

See how consistent materials can reduce your production variance and improve yield.

Solutions for Real Challenges

How we've helped customers solve specific production problems

- Ultrafine zirconium silicate

- Controlled D50: 1.2-1.5μm

- Narrow PSD distribution

- Optimized milling parameters

- Reduced oversize particles

- Improved dispersion protocol

- Application testing guidance

- Glaze formula consultation

- On-site technical visit

- High-purity zircon sand

- Controlled particle size 100-200 mesh

- Low impurity content

- Optimized particle grading

- Improved thermal shock resistance

- Enhanced packing density

- Formulation consultation

- Thermal testing guidance

- On-site technical support

- 3Y-TZP zirconia powder

- Controlled phase purity >98%

- Specific surface optimized

- Stabilizer content control

- Calcination temperature tuning

- Batch homogenization

- Sintering curve optimization

- Shrinkage data provision

- Ongoing technical dialogue

Have a similar challenge? Let's discuss how we can help solve it.

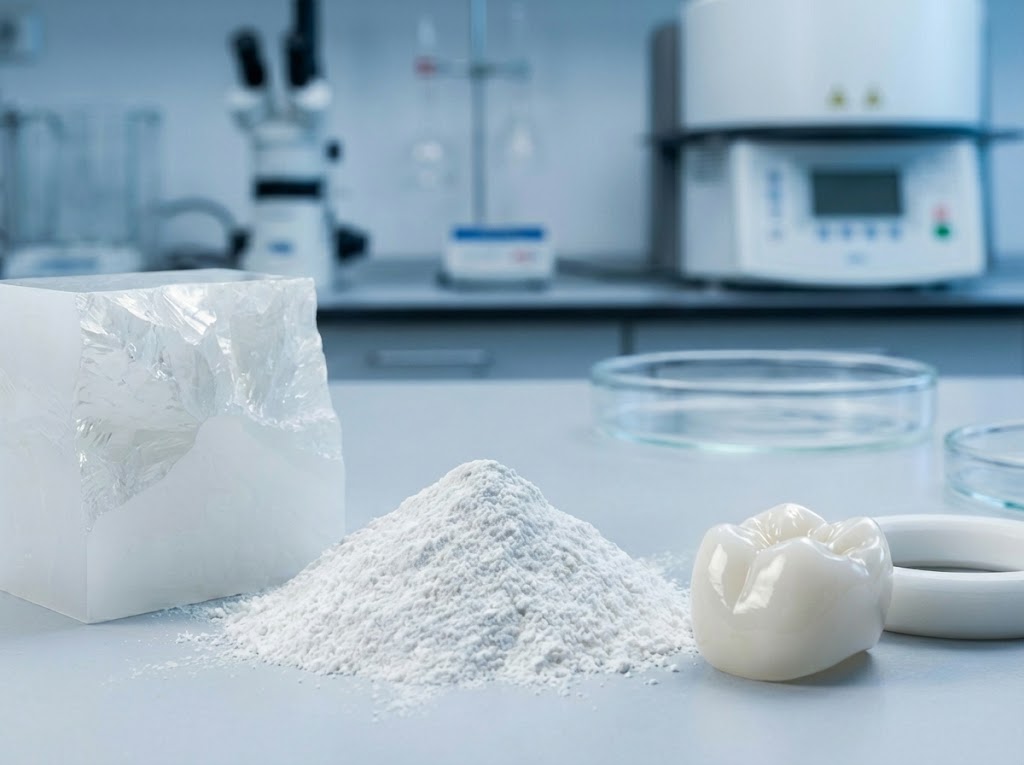

Product Portfolio

Comprehensive zircon materials engineered for specific performance requirements

High-Purity Zirconia (ZrO₂)

Our zirconia materials deliver exceptional phase stability and controlled particle characteristics for advanced ceramic applications. Available in stabilized and unstabilized grades to match your sintering requirements and end-use performance criteria.

Key Controllable Parameters

Primary Applications

Customizable Options

Zirconium Silicate (ZrSiO₄)

Premium zirconium silicate powders offering superior whiteness and opacity for ceramic glaze and body applications. Our controlled milling process ensures consistent particle distribution batch after batch for reliable production results.

Key Controllable Parameters

Primary Applications

Customizable Options

Zircon Powder & Sand

High-quality zircon flour and sand products for investment casting and refractory applications. Our strict source control and processing standards ensure consistent quality and reliable performance for demanding industrial specifications.

Key Controllable Parameters

Primary Applications

Customizable Options

Zirconia Structural Parts

Precision-engineered zirconia components manufactured from our own powder production. Complete vertical integration ensures material traceability and consistent mechanical properties for demanding industrial applications.

Key Controllable Parameters

Primary Applications

Customizable Options

Need help selecting the right grade for your application?

Quality Control & Testing

Rigorous testing protocols ensure every batch meets your specifications

Production & QC Process

Raw Material Inspection

Incoming ore and precursor materials tested for purity, composition, and radioactivity before entering production.

In-Process Monitoring

Critical parameters tracked during milling, calcination, and classification to maintain process consistency.

Laboratory Analysis

Comprehensive testing of particle size, chemical composition, phase analysis, and physical properties.

Final QC Release

Each batch verified against specifications before release. Non-conforming material quarantined and reprocessed.

Documentation & Traceability

Complete batch records maintained with full traceability from raw material to shipment.

Testing Parameters

Want to see a sample test report? We provide complete documentation with every shipment.

About ZrBrontec

A manufacturing partner, not just a trading company

We are a China-based zircon materials manufacturer with complete in-house production capabilities—from raw material processing to finished powder and structural parts. Our engineering team works directly with customers to solve application challenges, not just fulfill purchase orders.

Unlike trading companies that source from multiple suppliers with varying quality standards, we control every step of production. This means consistent material properties, full batch traceability, and the technical expertise to customize specifications for your specific requirements.

Our facility is open for customer visits and audits. We believe transparency builds long-term partnerships, and we're confident in showing you exactly how your materials are produced.

Want to learn more about our capabilities or schedule a facility visit?

Manufacturing & Workshop

Inside our production facility—where quality materials are made

High-Temperature Drying

Industrial drying kilns for zirconia materials with precise temperature control. Automated conveyor systems ensure uniform heat distribution and consistent moisture removal across all batches.

Powder Processing & Ball Milling

Large-scale ball milling systems for efficient grinding and particle size reduction. Multiple production lines ensure high throughput while maintaining precise control over powder characteristics.

Warehouse & Inventory

Spacious warehouse facilities with organized bulk storage in jumbo bags. Ready inventory ensures quick delivery and reliable supply chain for customer orders.

Production Facility

Modern manufacturing facility with ample space for production expansion. Purpose-built industrial buildings designed for efficient material processing and product handling.

Interested in seeing our facility firsthand? We welcome customer visits and audits.

How We Work

A structured approach to ensure the right material for your application

Application Discussion

Share your process requirements, performance criteria, and current challenges with our engineering team.

Grade Recommendation

Receive tailored product recommendations based on your specific application needs and industry standards.

Sample & Testing

Evaluate samples in your production environment with full technical data and application support.

Approval & Specs Lock

Finalize specifications, quality parameters, and documentation requirements for production orders.

Long-term Supply

Establish ongoing supply with consistent quality, reliable delivery, and continuous technical support.

Ready to start the conversation? Our engineers are here to help.

Insights & Technical Resources

Engineering knowledge, material science, and application guidance

Loading latest articles...

Looking for specific technical information? Our team can help answer your questions.

View All ResourcesFrequently Asked Questions

Direct answers to common procurement and technical questions

We maintain consistency through controlled raw material sourcing, standardized production parameters, and comprehensive testing at multiple production stages. Each batch undergoes full characterization including PSD, chemical composition, and phase analysis. Our quality system tracks historical data to detect any drift and adjust processes proactively. You receive complete test reports with every shipment for your incoming QC verification.

Yes, PSD customization is one of our core capabilities. We can adjust D10, D50, D90 values and control distribution width to match your process requirements. Share your target specifications and current challenges, and our engineers will evaluate feasibility and propose an optimized PSD profile. We typically validate custom specs through trial batches before production scale-up.

MOQ varies by product grade and customization level. For standard grades, our typical MOQ is 1 MT per grade. For custom specifications or special processing, MOQ may be 2-5 MT depending on complexity. We're flexible for qualification trials and can provide smaller sample quantities (25-100 kg) for testing purposes before committing to production volumes.

Absolutely. We prefer long-term partnerships over transactional relationships. Supply agreements can include locked specifications, scheduled delivery, safety stock arrangements, and price stability mechanisms. Long-term customers benefit from dedicated production slots, priority technical support, and collaborative product development for evolving application needs.

Standard grades typically ship within 2-3 weeks from order confirmation. Custom specifications or larger volumes may require 4-6 weeks. For long-term supply agreements, we maintain safety stock to ensure reliable delivery schedules. We recommend discussing your annual forecast so we can plan production capacity and maintain consistent supply for your operations.

Yes, we welcome customer visits and facility audits. Seeing our production capabilities firsthand helps build confidence in our partnership. We can arrange comprehensive factory tours covering raw material handling, production lines, QC laboratories, and warehousing. Contact us to schedule a visit—we'll coordinate logistics and prepare relevant technical discussions for your team.

Have a question not covered here? Our team is ready to help.

Start a Technical Discussion

Share your application details and let our engineers recommend the right solution

Get Your Free Expert Consultation

Connect with our engineers and receive tailored solutions for your specific application within 24 hours.

What Happens Next?

Our dedicated team ensures you get the support you need every step of the way.

Engineer Assignment

Your inquiry is reviewed and assigned to a technical engineer with expertise in your application area.

Technical Discussion

We'll reach out to discuss your requirements in detail and answer any technical questions.

Tailored Recommendation

Receive product recommendations, technical data sheets, and sample availability based on your specific needs.

Ongoing Support

Even after delivery, our engineers are available for follow-up technical support and optimization advice.

Engineer response within 24 hours (business days)