Selecting the correct ceramic material for extreme industrial environments often feels like a high-stakes gamble. You risk catastrophic equipment failure, safety hazards, and costly downtime if the material cannot withstand intense thermal stress or corrosion. Zirconia powder provides the exceptional durability and thermal stability your operations require, ensuring reliability across critical applications from aerospace to healthcare.

What is zirconia powder and its key properties?

Zirconia powder is a high-performance ceramic material composed of zirconium dioxide (ZrO2), renowned for its exceptional hardness and thermal resistance. This white crystalline oxide naturally occurs as baddeleyite but is synthesized into high-purity zirconia powder for demanding engineering tasks. Here’s the deal: unlike standard ceramics, it undergoes phase transformation toughening, which actively prevents crack propagation under stress.

Composition and phase structure

Pure zirconium dioxide exists in three crystal phases depending on the temperature: monoclinic, tetragonal, and cubic. At room temperature, the monoclinic phase is stable, but as you heat it, it transforms into the tetragonal phase. To prevent cracking during cooling, manufacturers add stabilizers like yttria (Y2O3). This creates a stable structure that allows you to utilize the material’s immense strength in room-temperature applications without failure.

High melting point characteristics

One of the most critical properties of this material is its extremely high melting point, reaching approximately 2,715°C (4,919°F). You might be wondering, how does this help your process? This capability allows components to survive in blast furnaces and jet engines where metals would instantly melt. It acts as a robust thermal barrier, shielding sensitive machinery from destructive heat while maintaining structural integrity.

Chemical corrosion resistance

Zirconia exhibits profound inertness when exposed to aggressive acids, alkalis, and solvents. In chemical processing, this means your pumps and valves remain unaffected by corrosive slurries that typically degrade metal alloys. This resistance prevents contamination in high-purity environments, ensuring that the final product remains uncompromised by the reactor material itself.

Key TakeawayZirconia powder stands out due to its unique combination of thermal, mechanical, and chemical resilience. It is not just a heat shield; it is a structural material capable of enduring the harshest industrial environments.

| Property | Value / Characteristic | Industrial Impact | |

|---|---|---|---|

| Melting Point | ~2,715°C | Enables operation in extreme heat zones. | |

| Hardness | 8.5 (Mohs) | Provides superior wear resistance. | |

| Thermal Conductivity | Low (< 2 W/m·K) | Acts as an effective thermal insulator. | |

| Chemical Inertness | High | Prevents corrosion and contamination. |

Zirconia’s unique phase transformation mechanism effectively acts as a self-healing process, closing micro-cracks before they lead to failure.

How is zirconia powder produced via chemical methods?

Chemical production methods involve dissolving zirconium salts and precipitating them to create fine, high-purity zirconia powder. This route allows manufacturers to precisely control particle size and purity, which is essential for high-tech applications.

Chemical Precipitation Method

This is the most common technique for mass production due to its scalability and cost-efficiency. Zirconium salts are dissolved in water and reacted with a base like ammonia to precipitate zirconium hydroxide. But here’s the kicker… rigorous washing is required to remove impurities that could cause agglomeration during the sintering process .

Sol-Gel Process details

The Sol-Gel process provides superior control over the chemical composition at the molecular level. It transitions a liquid solution (sol) into a solid gel phase, trapping dopants uniformly within the matrix. This results in ultrafine powders with high surface capability, allowing you to sinter the material at lower temperatures while achieving full density.

Hydrothermal reaction steps

- Precursor Mixing: Zirconium salts are mixed with water in a sealed vessel.

- Heating: The solution is heated above the boiling point of water (150°C–300°C).

- Crystallization: High pressure forces the formation of crystalline powder directly from the solution.

Key TakeawayChemical synthesis routes offer the precision required for advanced ceramics, balancing cost against purity and particle morphology.

| Method | Primary Advantage | Typical Application | |

|---|---|---|---|

| Precipitation | Cost-effective, scalable | Bulk industrial ceramics | |

| Sol-Gel | Molecular homogeneity | High-performance coatings | |

| Hydrothermal | Direct crystalline formation | Nanomaterials, Electronics |

The choice of production method dictates the sintering behavior and final strength of the ceramic component.

Which advanced techniques create zirconia powder?

Advanced techniques create zirconia powder through direct oxidation, vapor deposition, or electrolysis to achieve specific nanostructures or extreme purity levels. These methods are typically reserved for specialized applications where standard chemical precipitation falls short.

Direct Oxidation Method

This process involves the combustion of zirconium metal powder in an oxygen-rich environment. While it yields very pure oxides, the reaction is highly exothermic and requires strict temperature management to prevent safety incidents. What’s the real story? It often requires subsequent milling to reduce particle size, which can reintroduce impurities if not handled carefully.

Vapor Deposition Method

Chemical Vapor Deposition (CVD) synthesizes powder by reacting volatile precursors in the gas phase. This eliminates the liquid byproducts associated with precipitation and allows for the creation of non-agglomerated nanoparticles. You get discrete, uniform particles that are ideal for high-end sensors and optical coatings.

Electrolytic Method process

- Electrolysis: Current is passed through a zirconium salt bath.

- Deposition: Zirconium oxide forms at the electrode.

- Refining: The process simultaneously purifies the material.

Key TakeawayAdvanced synthesis techniques prioritize purity and particle morphology over volume, catering to high-tech sectors like photonics and electronics.

| Technique | Key Feature | Best For | |

|---|---|---|---|

| Direct Oxidation | High purity base | Electronic substrates | |

| Vapor Deposition | Nano-scale control | Sensors, Optical films | |

| Electrolytic | Simultaneous refining | Specialized refractory |

Vapor deposition offers the highest degree of control over particle size distribution, critical for nanotechnology applications.

Why is zirconia powder preferred for dental applications?

Zirconia powder is preferred for dental applications because it combines the strength of metal with the aesthetic appeal of natural teeth. It allows dentists to provide restorations that are both durable and visually indistinguishable from enamel.

Benefits for dental crowns

Monolithic zirconia crowns offer superior fracture resistance compared to porcelain-fused-to-metal options. This strength allows for thinner crown walls, meaning you preserve more of the patient’s natural tooth structure during preparation. Ready for the good part? Modern formulations are highly translucent, eliminating the “chalky” look of older ceramics.

Aesthetic and transparency factors

- Translucency: Mimics the light-scattering of natural dentin.

- Color Matching: Can be shaded to match any tooth shade perfectly.

- Stain Resistance: Highly polished surfaces resist coffee and tea stains.

Durability under mechanical stress

The oral environment subjects materials to constant biting forces and thermal cycling. Zirconia’s transformation toughening mechanism stops micro-cracks from spreading, preventing catastrophic failure. This reliability makes it the gold standard for long-span bridges where other ceramics would snap under load.

Key TakeawayZirconia has revolutionized dentistry by offering a material that satisfies both the structural demands of chewing and the cosmetic demands of the patient.

| Feature | Zirconia Benefit | Patient Outcome | |

|---|---|---|---|

| Strength | >900 MPa flexural strength | Fewer broken crowns | |

| Aesthetics | High translucency | Natural-looking smile | |

| Biocompatibility | Metal-free | No allergic reactions |

The elimination of metal substructures removes the risk of dark lines appearing at the gumline over time.

How does zirconia powder improve industrial cutting tools?

Zirconia powder improves industrial cutting tools by providing extreme hardness and heat resistance that significantly extends tool life. It outperforms traditional steel in specific applications involving abrasive or adhesive materials.

Advantages over traditional steel

Zirconia blades maintain a razor-sharp edge far longer than stainless steel counterparts when cutting abrasive materials like paper or Kevlar. They are chemically inert, meaning they won’t rust or react with the materials being cut. Here’s the deal: this eliminates the need for oil coatings, preventing contamination of sensitive products like medical films.

Heat stability in friction

High-speed cutting generates intense heat that softens steel edges, leading to dullness. Zirconia retains its hardness at elevated temperatures, allowing for faster processing speeds without degrading the tool. The low coefficient of friction also helps chips slide off the tool face, reducing heat buildup in the first place.

Fracture toughness mechanisms

- Shock Resistance: Stabilized zirconia resists chipping during interrupted cuts.

- Flexural Strength: Withstands bending forces better than alumina.

- Edge Retention: Maintains geometry for precision slicing.

Key TakeawayFor specific non-metallic cutting applications, technical ceramics like zirconia offer superior longevity and cleanliness compared to metal tools.

| Characteristic | Zirconia Tool | Steel Tool | |

|---|---|---|---|

| Edge Life | Extremely Long | Moderate | |

| Corrosion | None (Inert) | Prone to rust | |

| Maintenance | Low (No oiling) | High (Sharpening/Oiling) |

While not suited for high-impact metal machining, zirconia is unrivaled for slicing abrasive composites and soft tissues.

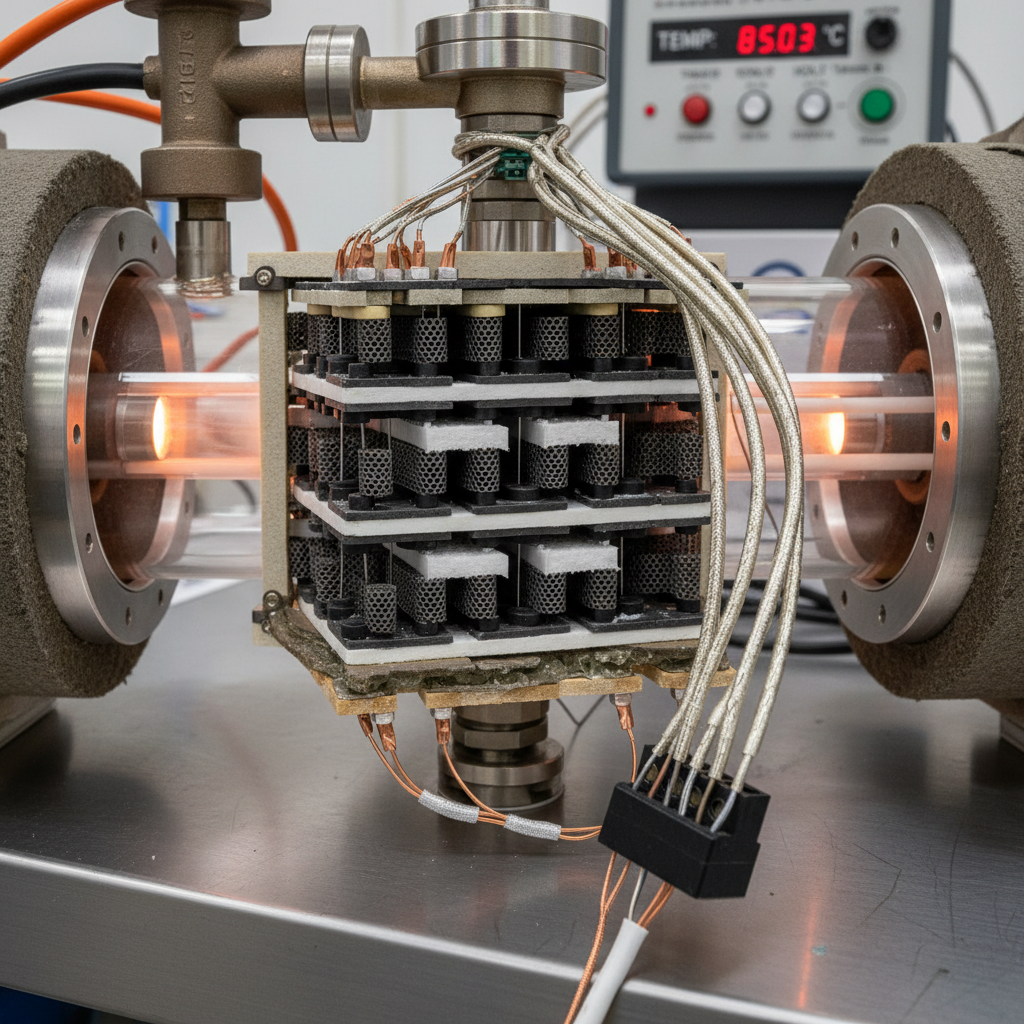

How does zirconia powder function in energy systems?

Zirconia powder functions as the critical electrolyte material in Solid Oxide Fuel Cells (SOFCs), enabling the efficient conversion of chemical energy into electricity. Its unique ability to conduct oxygen ions at high temperatures drives the electrochemical reaction.

Solid Oxide Fuel Cells (SOFC) role

In an SOFC, yttria-stabilized zirconia (YSZ) acts as a solid membrane that separates the fuel from the air. It must be gas-tight to prevent fuel leakage while allowing oxygen ions to migrate through its crystal lattice. This is where it gets interesting: this process generates electricity without burning the fuel, resulting in much higher efficiency than combustion engines.

High ionic conductivity

- Oxygen Vacancies: Doping creates gaps in the lattice for ion movement.

- Temp Dependence: Conductivity increases significantly above 700°C.

- Efficiency: Lower resistance leads to higher power output.

Efficiency and emission reduction

SOFCs utilizing zirconia electrolytes can achieve electrical efficiencies exceeding 60%. Because they operate at high temperatures, they can internally reform fuels like natural gas and biogas. This flexibility reduces the need for external processing equipment and lowers overall system emissions.

Key TakeawayZirconia is the enabling technology for SOFCs, providing the ionic conductivity and stability required for clean, continuous power generation.

| Component | Function | Property Required | |

|---|---|---|---|

| Electrolyte | Ion Transport | High Ionic Conductivity | |

| Anode Support | Structural Base | Mechanical Strength | |

| Interconnect | Cell Connection | Thermal Expansion Match |

The high operating temperature of zirconia-based cells makes them ideal for combined heat and power (CHP) systems.

Why use zirconia powder in high-temperature refractories?

You use zirconia powder in high-temperature refractories because it remains stable at temperatures where other ceramics melt or fail. It is indispensable for lining furnaces used in steel and glass production.

Withstanding extreme industrial heat

Standard silica bricks fail around 1,800°C, but zirconia refractories withstand temperatures exceeding 2,000°C. This thermal headroom allows operators to run kilns hotter, improving throughput and melt quality. But here’s the kicker… it also resists thermal shock, preventing the bricks from cracking during rapid temperature changes.

Resistance to molten metals

- Non-wetting: Molten steel does not stick to zirconia surfaces.

- Corrosion Resistance: Prevents slag from eating into the lining.

- Purity: Does not dissolve into and contaminate glass melts.

Structural support in kilns

Refractory materials made from zirconia are used as setters and supports because they resist “creep”—the tendency to deform under load at heat. This ensures that the ware being fired remains flat and dimensionally accurate.

Key TakeawayZirconia refractories extend the campaign life of industrial furnaces, reducing maintenance costs and preventing catastrophic lining failures.

| Application | Zirconia Benefit | Operational Gain | |

|---|---|---|---|

| Glass Melting | Corrosion Resistance | Higher glass quality | |

| Steel Casting | Thermal Shock Resist | Longer nozzle life | |

| Kiln Furniture | Creep Resistance | Better product geometry |

Its resistance to wetting by molten metals is the primary reason it is used in continuous casting nozzles.

How is zirconia powder utilized in biomedical implants?

Zirconia powder is utilized in biomedical implants to create hip and knee joints that are biocompatible and exceptionally wear-resistant. It offers a longer-lasting alternative to metal and polyethylene components for younger, active patients.

Orthopedic joint replacements

Zirconia ceramic femoral heads provide a smooth, hard surface that articulates against the hip cup. You might be wondering, why is this better than metal? Metal heads can scratch over time, acting like sandpaper that wears down the cup. Zirconia maintains its polish indefinitely, preserving the integrity of the entire joint assembly.

High wear resistance benefits

- Low Friction: Reduces wear on mating polyethylene liners.

- Debris Reduction: Minimizes particle release that causes inflammation.

- Longevity: Extends the functional life of the implant by decades.

Corrosion resistance in biology

The human body is a corrosive saline environment that attacks metals over time. Zirconia is bio-inert, meaning it does not corrode or release ions into the bloodstream. This chemical stability prevents adverse tissue reactions and ensures the implant remains safe for permanent use.

Key TakeawayBiomedical zirconia improves patient quality of life by reducing the frequency of revision surgeries caused by implant wear and loosening.

| Implant Type | Zirconia Advantage | Comparison to Metal | |

|---|---|---|---|

| Hip Head | Ultra-smooth surface | Lower wear rate | |

| Knee Tray | Bio-inertness | No metal ion release | |

| Bone Screw | Osseointegration | No corrosion |

The reduction in wear debris is the single most important factor in preventing long-term implant loosening.

Is zirconia powder safe for human handling and use?

Zirconia powder is generally safe for human handling and use, provided standard industrial hygiene protocols are followed. It is chemically non-toxic and biocompatible, but the physical dust requires management.

Toxicity and biocompatibility

Chemically, zirconium dioxide is inert and does not dissolve in body fluids, which is why it is safe for implants. In powder form, it is classified as a “nuisance dust.” Here’s the deal: while not poisonous, inhaling large quantities can mechanically irritate the lungs, so controlling airborne dust is essential.

Radioactivity concerns addressed

- Natural Origin: Raw zirconium ore contains trace uranium/thorium.

- Purification: Chemical processing removes these isotopes.

- Certification: Medical-grade powder is tested to ensure radiation is negligible.

Safe handling protocols

To maintain a safe environment, workers must follow safe handling protocols such as wearing N95 respirators and using local exhaust ventilation. You should avoid dry sweeping to prevent creating dust clouds; instead, use HEPA vacuums or wet cleaning methods.

Key TakeawayZirconia is chemically safe, but physical dust management is required to meet OSHA standards and ensure worker comfort.

| Hazard | Risk Level | Mitigation | |

|---|---|---|---|

| Chemical Toxicity | Very Low | None required | |

| Inhalation | Moderate (Dust) | N95 Mask, Ventilation | |

| Radioactivity | Negligible | Buy purified grades |

Proper ventilation and PPE effectively eliminate the primary risks associated with handling fine ceramic powders.

What defines the future outlook for zirconia powder?

The future outlook for zirconia powder is defined by its expansion into nanotechnology, solid-state batteries, and additive manufacturing. As industries demand higher performance and miniaturization, zirconia’s role continues to grow.

Expanding high-tech applications

Emerging technologies are leveraging zirconia for transparent armor, scratch-resistant smartphone screens, and advanced sensors. Ready for the good part? 3D printing is unlocking geometries that were previously impossible to machine, allowing for custom-designed chemical reactors and complex aerospace heat shields.

Summary of industrial versatility

- Electronics: Insulating layers and oxygen sensors.

- Energy: Solid-state electrolytes for next-gen batteries.

- Consumer: Wearables and luxury ceramic watches.

Market demand growth factors

The drive for clean energy and better healthcare is fueling a sustained increase in demand for high-purity zirconia powder. As production costs decrease and powder quality improves, you will see this material replacing metals in an even wider array of everyday and industrial applications.

Key TakeawayZirconia is transitioning from a niche refractory material to a cornerstone of modern high-tech manufacturing and clean energy systems.

| Sector | Future Application | Driver | |

|---|---|---|---|

| Mobile | Ceramic backplates | 5G signal transparency | |

| Auto | Solid-state batteries | Safety & Range | |

| Medical | 3D printed implants | Custom patient fit |

The ability to 3D print zirconia will democratize access to high-performance ceramic components for small-batch manufacturers.

Conclusion

Zirconia powder represents the pinnacle of ceramic engineering, offering a unique blend of toughness, thermal stability, and biocompatibility that no other material can match. By understanding its production methods, diverse applications, and safety profile, businesses can leverage this material to solve complex engineering challenges and drive innovation. Whether improving patient outcomes in healthcare or boosting efficiency in energy systems, zirconia stands as a pillar of modern technology. For high-purity supply and expert guidance, contact us today to discuss your specific requirements. We are committed to powering the future of industry with advanced material solutions.

FAQ

Q1: What is zirconia powder primarily used for?Zirconia powder is primarily used to manufacture advanced ceramics for dental crowns, orthopedic implants, solid oxide fuel cells (SOFC), and industrial cutting tools. It is the material of choice for these applications because it offers exceptional fracture toughness, chemical inertness, and thermal stability that metals and other ceramics cannot match.

Q2: How does yttria-stabilized zirconia (YSZ) prevent cracking?YSZ prevents cracking through a mechanism called “transformation toughening.” When a crack attempts to propagate through the material, the crystal structure locally transforms from tetragonal to monoclinic, which causes a volume expansion. This expansion actively squeezes the crack shut, stopping it in its tracks and significantly increasing the component’s durability.

Q3: Is zirconia powder dangerous to inhale?Yes, inhaling high concentrations of zirconia powder can be hazardous as a respiratory irritant, known as “nuisance dust.” While the material itself is chemically non-toxic, you must use proper ventilation and Personal Protective Equipment (PPE) like N95 masks to prevent mechanical irritation of the lungs and throat during handling.

Q4: Can zirconia withstand rapid temperature changes?Yes, zirconia has good thermal shock resistance compared to many other ceramics, particularly when used in refractory applications. Its high melting point (~2,715°C) and low thermal conductivity allow it to withstand extreme thermal cycling in jet engines and industrial furnaces without failing or spalling.

Q5: How do I know if I need high-purity zirconia powder?You need high-purity zirconia powder if your application involves high-tech electronics, biomedical implants, or critical load-bearing components. Impurities like silica or sodium can form glassy phases at grain boundaries that weaken the material and reduce its corrosion resistance, so demanding applications always require chemically precipitated, high-purity grades.